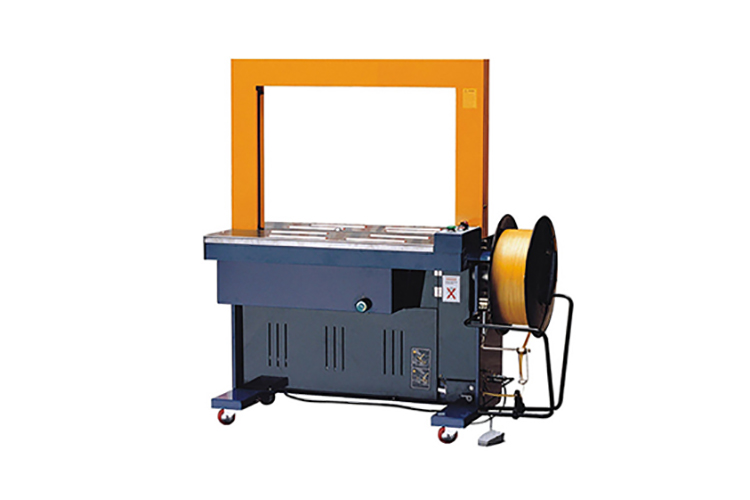

Principle and performance characteristics of automatic strapping machine

automatic strapping machine, also known as automatic strapping machine, is one of the commonly used post packaging machines. Automatic strapping machine mainly uses mechanical force to help people pack products and improve packaging efficiency. In the past, manual packaging was time-consuming, low in efficiency, and relatively high labor costs. The emergence of automatic packaging machines saves labor costs, improves resource utilization, reduces investment costs, and is welcomed by many mass production companies.

Principle of automatic strapping machine.

The principle of the packaging machine is not very complicated, much like we usually tie up bags, cartons, etc., use ropes to entangle the objects, and then tie the knots to reinforce them. The packaging machine is completed by mechanical power, and the packaging objects are placed on the automatic In the middle of the panel of the packaging machine, through the induction device on the panel (also can be operated manually), the line device of the machine is put into the line rack of the packaging machine, and then the lines on the same pair of line racks are contracted to make the packaging machine close to the packaging machine. On the surface, the packaging machine is heated to melt and bond the two ends of the packaging machine, and then cut, the entire packaging process is completed.

Performance characteristics:

1. Programmable controller control, stable performance.

2. Automatic detection, automatic packaging, automation and high efficiency.

3. Imported electrical equipment configuration, longer service life.

4. You can choose an automatic alarm device to automatically alarm for loss and failure.

5. It can be used alone or in conjunction with an unmanned packaging line.

The automatic strapping machine is easy to operate, has the advantages of high work efficiency, time and power saving, high packaging quality, low failure rate and long service life. Mainly used in business services, postal, railway, banking, food, medical, books and other industries.