Do you know how to maintain the twister?

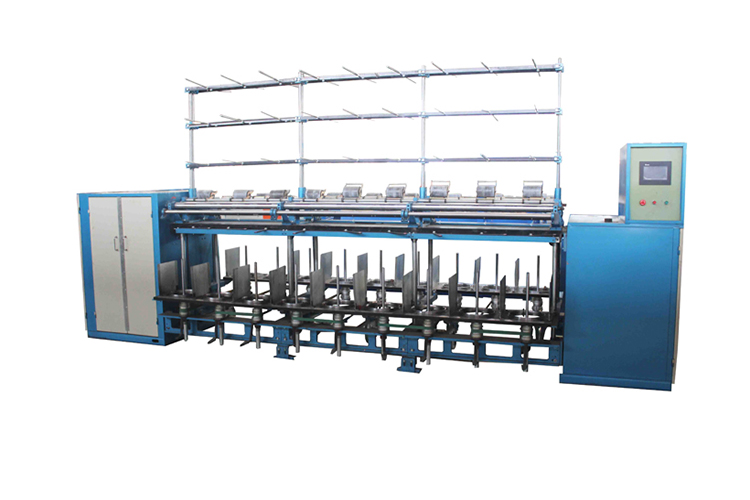

Needlework is often seen in our lives, and twisting machines are not unfamiliar. The maintenance of twisting machines is very important in daily production. Let's take everyone to take a look at how to maintain twisting machines!

Check the flexibility of the spindle operation, unload the spindle, grasp the stop plate, and quietly roll the rotating plate, check whether there is abnormal noise during the rolling motion, and whether it is lack of oil. If the spindle is found to be malfunctioning, pull out the stop plate forcefully to separate the stop plate from the rotating plate. Check whether there is any waste wire wrapped around the spindle bearing, remove if there is any, and check the flexibility of the bearing. There is no waste wire around, but the bearing rotation is not active. Perhaps the bearing is still not active after the waste wire is removed. Then use a special fixture to remove the bearing and replace it with a new bearing. Use a tubular clamp to hold the inner ring of the bearing and press the bearing in. After applying low-torque grease on the outer surface of the bearing, press in the stop plate. If the spindle feet are short of oil, they should be refueled immediately.

Check whether the dragon belt makes abnormal noise, whether it moves up and down, whether there is waste wire wrapped, whether it is stained with oil. Check that the dragon belt does not touch the upper and lower limit wheels. If it touches the height of the tension wheel that needs to be adjusted, adjust it from the side of the automatic belt reel. When twisting right, the tangled belt rolls clockwise, so when adjusting, start from the automatic belt reel and check it clockwise for a week. The up and down movement of the dragon belt is also caused by the improper high and low position of the tension wheel. If there is waste silk wrapped around the dragon belt, a small amount can be processed when the machine is stopped. In many cases, it needs to be processed immediately, otherwise the dragon belt will slip and make abnormal noises.

When the dragon belt is seriously polluted, the spindle speed will be reduced and an abnormal sound will be announced, so the dragon belt should be removed and cleaned with neutral detergent. When the belt is driven, it passes through the outside of the tension wheel and the inside of the belt. The primary function of the tension wheel is to maintain the tension of the belt to ensure that the transmission does not slip. When adjusting the tension wheel, make sure that the tension wheel rolls flexibly. If the tension wheel does not roll flexibly, the dragon belt will be worn. At the same time, ensure the smooth transmission of the tensioning wheel. The top roller rod should be checked for flexibility and for wire winding. If there is a yarn winding, it can be processed at the end of the time when a small amount of yarn is wound. If there are many winding wires, it will affect its transmission, and it should be handled immediately.

The above is the maintenance of the twisting machine, I hope it can be helpful to everyone!