Deep analysis of plastic granulator

Features of plastic granulator

After the plastic parts are added to the hopper, the hopper steadily falls on the screw and is bitten by the screw. As the screw rotates, the screw is pressed in the direction of the machine head, and the mechanical transport is completed. As the screw depth of the screw gradually decreases, when the plastic moves from the supply port to the direction of the machine head, due to the existence of resistances such as filters, manifolds, and machine heads, the plastic forms high pressure during the plasticization process, which makes the material dense and improves it. The thermal conductivity helps the plastic melt quickly, and the pressure gradually increases, and the gas originally existing between the particles is discharged from the exhaust hole.

When the pressure increases, the plastic is heated on the one hand, and on the other hand, the plastic itself will also generate a lot of heat due to internal friction during the compression, feeding and stirring processes. Under the combined action of external and internal forces, the temperature of the plastic gradually decreases, and its physical state also changes from glass state to high elastic state to viscous state.

Principle of plastic granulator

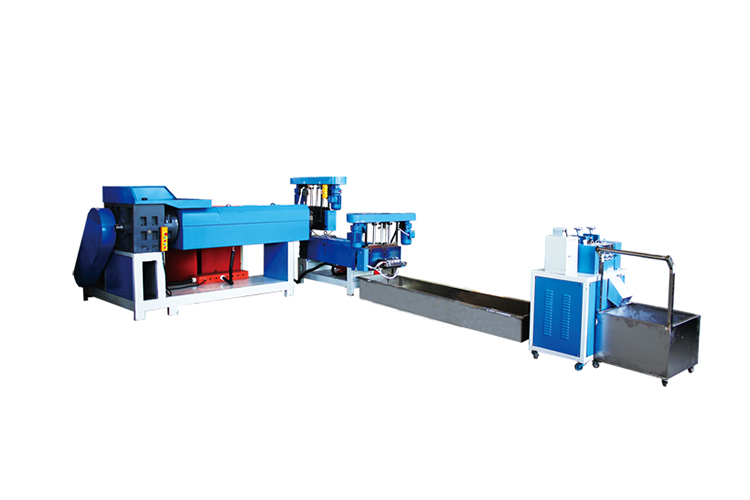

The main device of the plastic granulator is the extruder system, including the extrusion system, the conveying system and the heating and cooling system.

Extruder system: The extruder system consists of screw, barrel, hopper, head, die, etc. The plastic forms a uniform melt through the extrusion system, and pressure is formed in the process to continuously extrude the screw.

1. Screw: It is the main component of the extruder and is made of high-strength corrosion-resistant alloy steel, which is directly related to the scope of use and production efficiency of the extruder.

2. Cylinder: The metal seamless tube is generally made of heat-resistant, high-pressure-resistant, strong, and corrosion-resistant alloy steel or composite steel pipe lined with alloy steel. Through the cooperation with the screw, the plastic can be crushed, softened, melted, plasticized, emptied, and compacted, and the rubber material can be continuously and uniformly transported to the molding system. In order to fully heat the plastic and fully plasticize the principle, the length of the ordinary cylinder is 18:1 of its diameter.

3. Funnel: There is a cut-off device at the bottom of the funnel, which can adjust and cut off the flow of the funnel. The side of the funnel is equipped with a sight hole and a calibration metering device.

4. Machine head and mold: The machine head is composed of a carbon steel shell and an inner layer of alloy steel, and the inner layer is equipped with a forming mold.

Failure and maintenance of plastic granulator.

1. The current of the host is unstable, the feed is uneven, the bearing of the host is damaged or the connection is poor, and it cannot be heated. Some water heaters are abnormal or have incorrect phases, screw adjustment pads are incorrect, and components interfere.

Check the feeder, troubleshoot, and replace the bearings if necessary. Check the main motor and replace the water heater if necessary. Check whether the water heaters are working normally, pull out the screws to check whether the screws interfere, and check the adjustment pads.

2. The main motor cannot be started: the drive sequence is not correct, check whether the fuse is burnt; the main motor coil has a problem; the chain reaction related to the main motor.

Drive in the correct driving sequence again, check the sequence, check the main motor circuit, and check the connection related to the main motor. If the oil pump is not turned on, please check whether the oil pump is started. The motor cannot be turned on, the total power supply is turned off, and it starts after 5 minutes. The induction current of the inverter is not disconnected. Check whether the emergency button is reset.

3. Poor discharge or blockage of the machine head: A certain part of the heater with poor plasticization of the material does not work, or the viscosity distribution of the plastic is wide. Low temperature regulation and unstable operation. There may be metals that are not easy to melt.

If it needs to be replaced, please check the heater and consult with the staff. Confirm the set temperature of each part; increase the set temperature; remove the extrusion system and pressure head.

To correctly understand the working principle of the plastic granulator, the granulator must be used and maintained correctly.